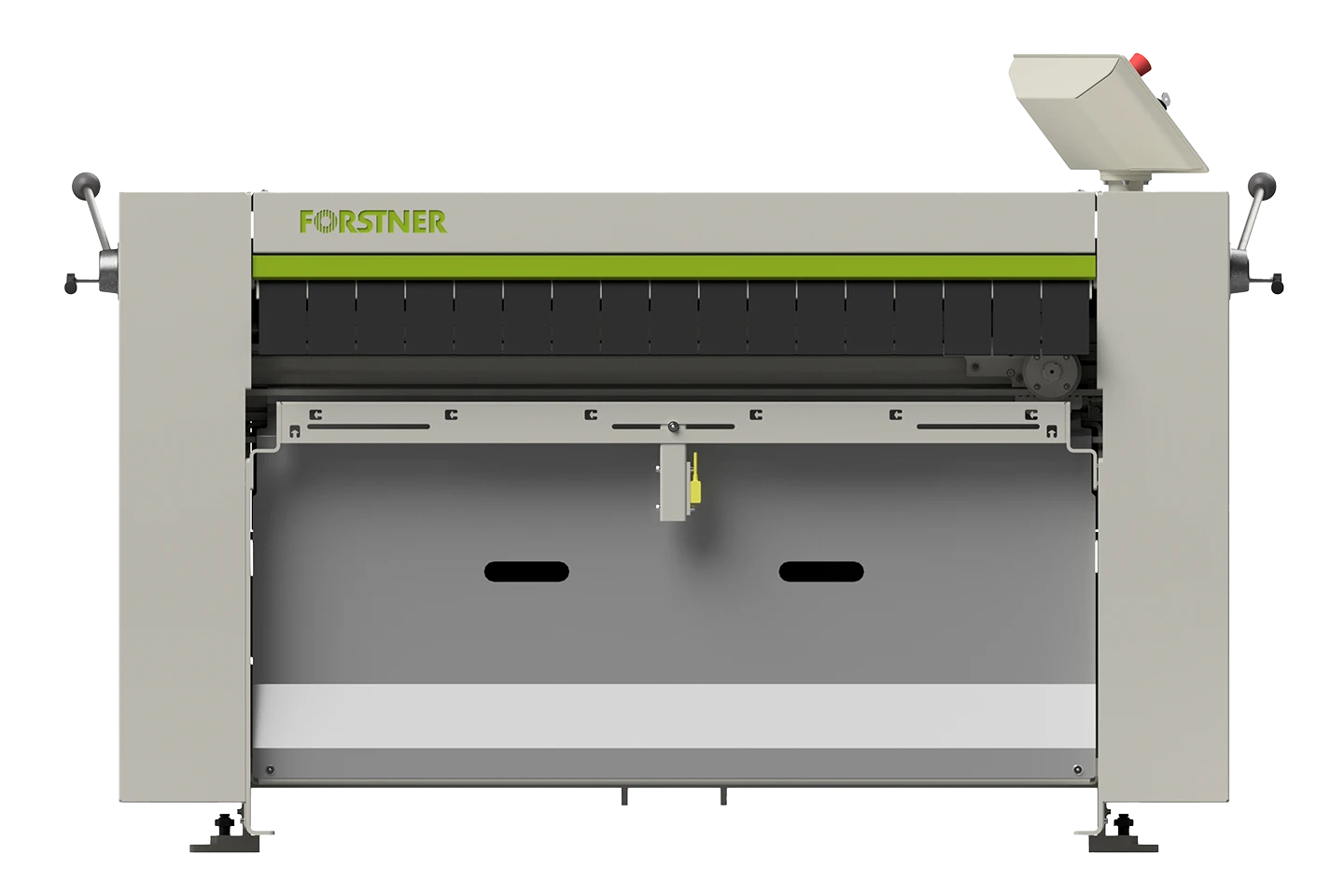

Forstner EASY

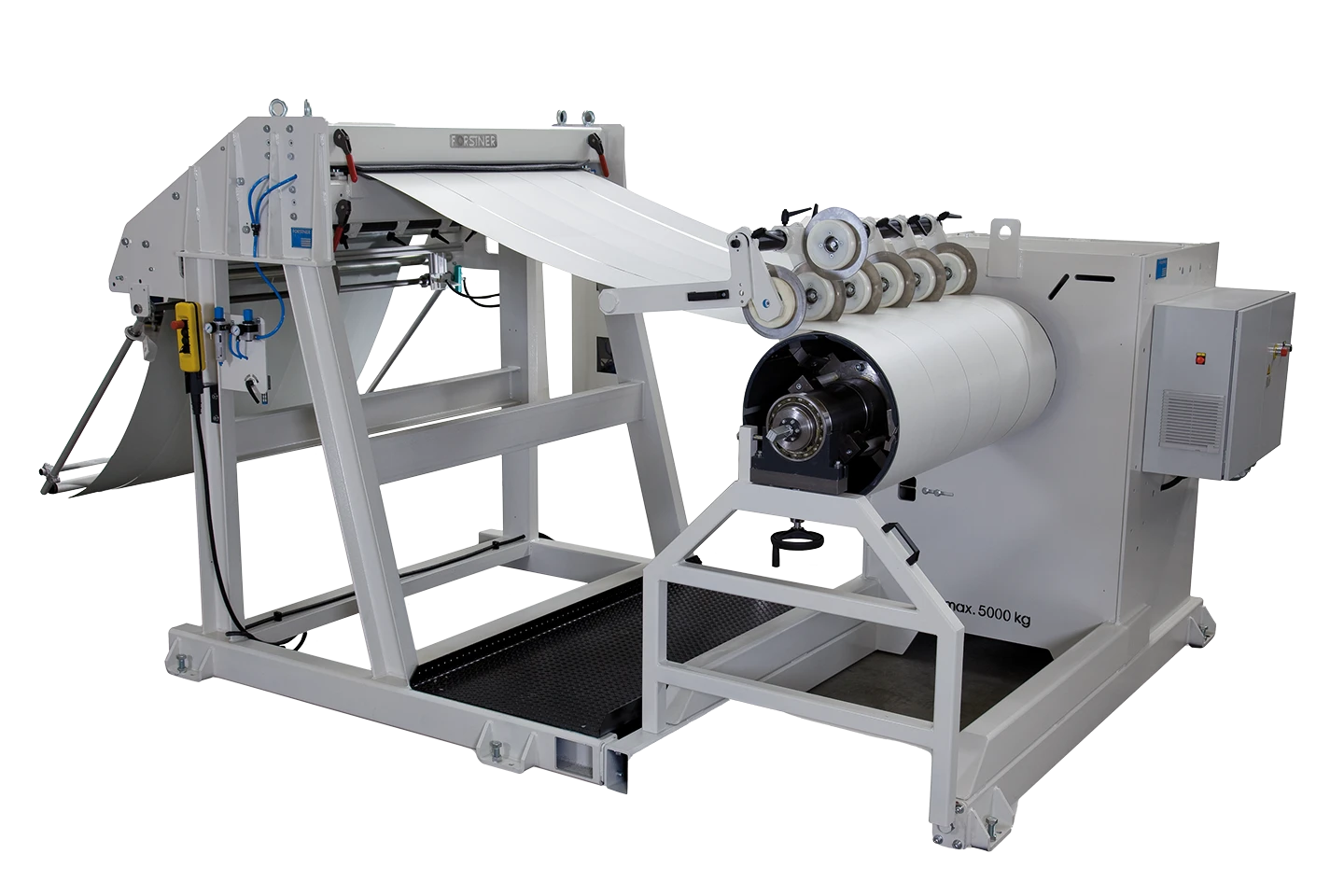

Forstner EASY is a user-friendly Cut to Length for coil processing, where the user easily sets lengths and quantities. It straightens and cuts sheet metal with high precision. Available as EASY CUT with slitting shear for standard capacity and EASY PRO with guillotine shear for increased cutting capacity, both with minimal waste and burr-free cuts.

EASY

Smart Advantages

- Small and compact yet very powerful

- Straightener with three rollers

- Smart and user-friendly control system

- High feeding speed

- Easy-to-use machine

- Simplest possible adjustment of slitting knives

Key advantages

Easy and intuitive control system

Efficient with low maintenance requirements

Suitable for a wide range of materials commonly used in the construction industry

Capacity

Unmatched precision and flexibility.

Working length

1250

Speed

25 m/min

Steel thickness

1,5 – 1,0

Straightener

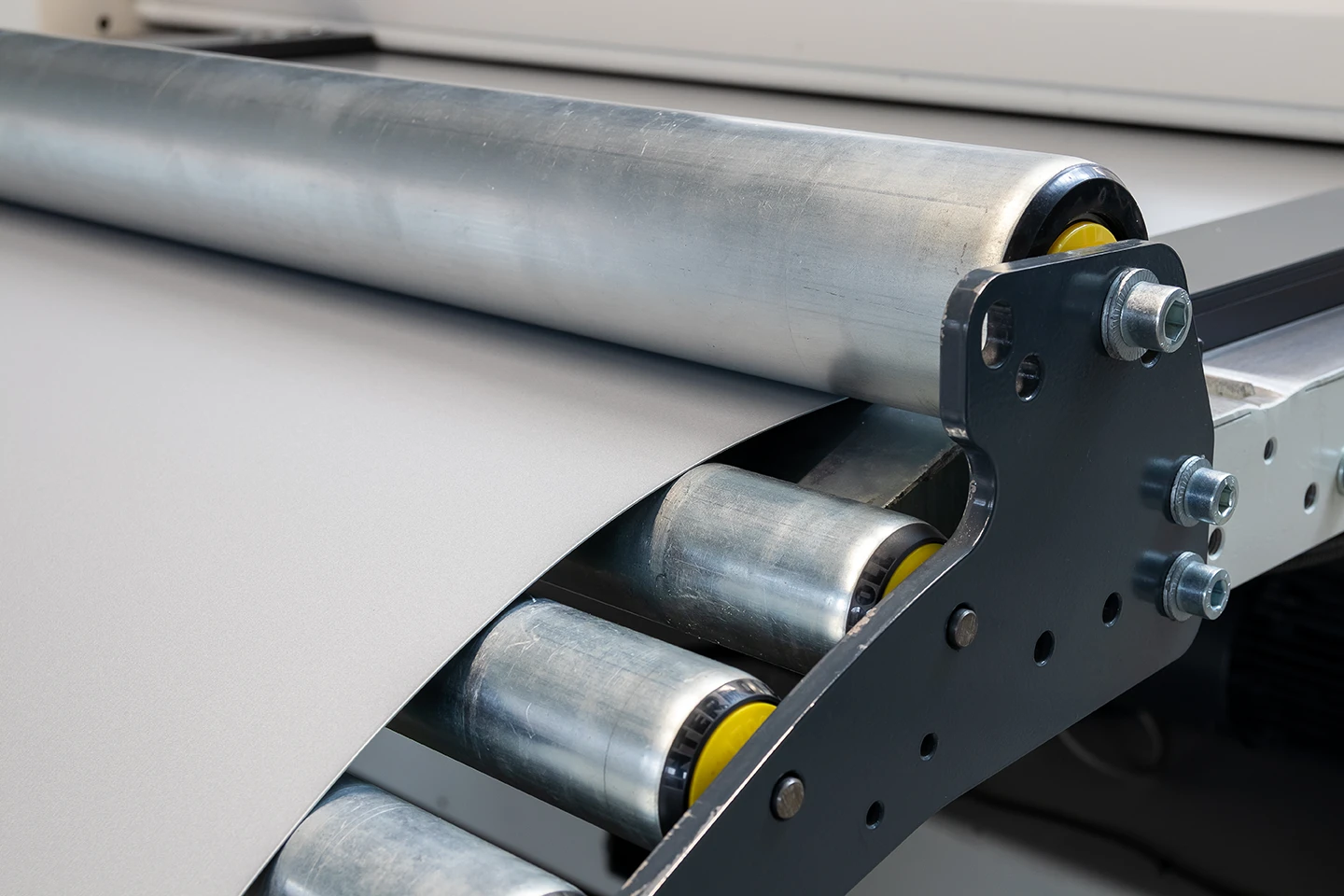

The EASY series is equipped with 3 manual straightening rollers that eliminate coil memory and consistently deliver straightened material. The rollers are made of polished steel and have a diameter of 70 mm. The pressure on the straightening rollers is adjusted with lockable handles equipped with a reference scale.

Infeed Guide

The rollers of the infeed guide are angled to match the loop of the material from a decoiler. This prevents damage and creases to softer materials such as copper, aluminum, and zinc.

Control system S1

S1 control system with touchscreen and intuitive functions. It is easy to program different quantities and lengths. The control system communicates with an electronic eye and automatically sets the zero point and performs a perpendicular clean cut. The control system has a material-saving function that stops the machine, raises the slitting knives, and feeds the sheet forward to the shear. An optional wireless remote control can operate a motorized decoiler or recoiler.

Infeed Table

The infeed table has four ball-bearing rollers that guide the sheet metal to the infeed rollers. Thanks to the ball bearings, the sheet metal can be fed forward and backward without the risk of damaging the edges. They also help keep the material parallel and ensure perpendicular cuts.

OPTION

Film applicator

The film applicator can basically be mounted on any table. Using the deflection rollers and the fully rubberized feed rollers, the protective film is pressed on almost bubble and wrinkle-free. The device type F-AG z2mo has an additional arm with tension spring for tensioning the film during the return movement. This design is only applicable for single decoiling systems. Film applicator available in both 1250 and 1500 mm.

OPTION

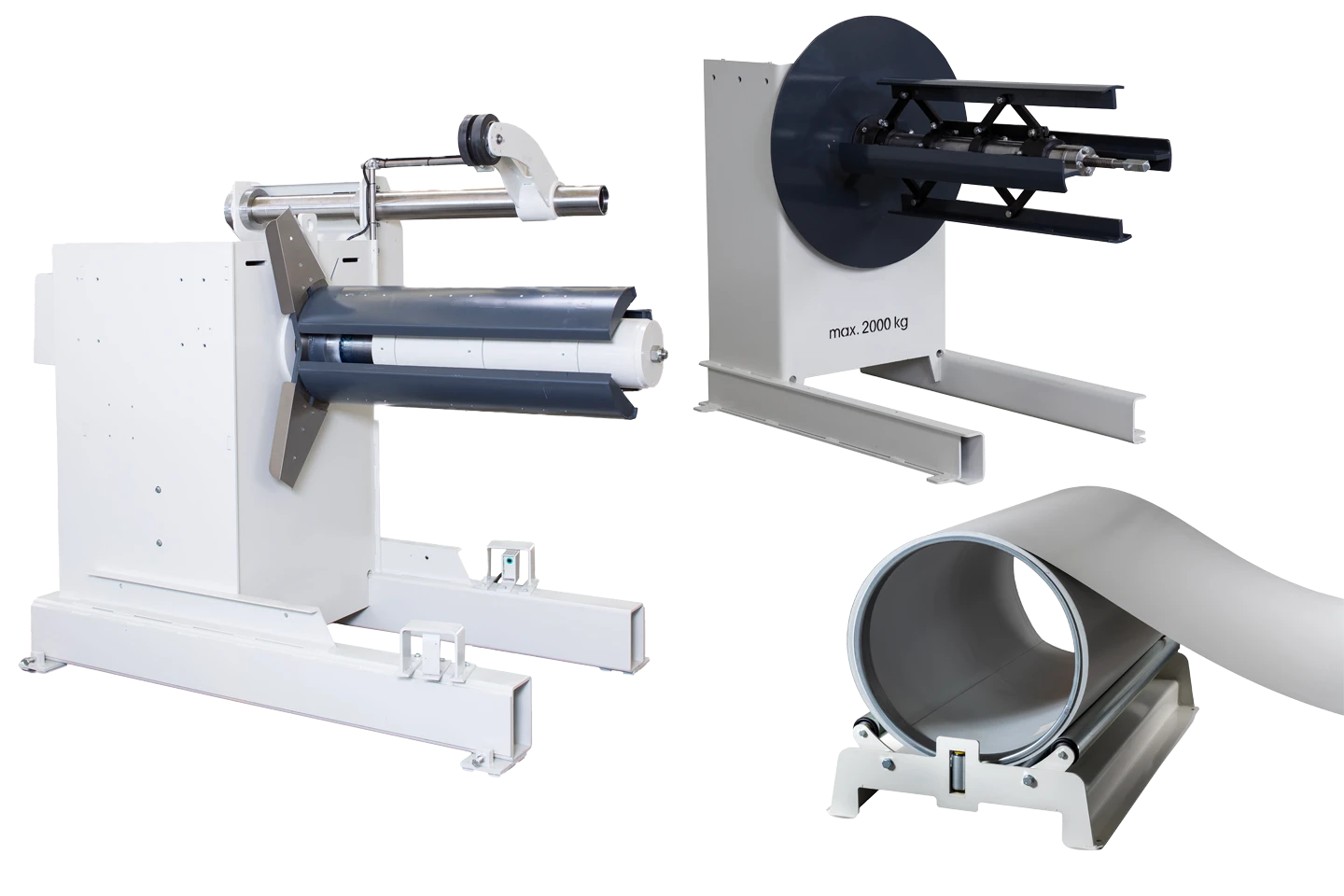

Decoiler units

Choose from a simple cradle up to motorized versions. Read more under respectively product.

OPTION

Foot switch

Add a foot switch to your machine in the EASY series for external start of next order.

OPTION

Manual coilselector

The manual coilselector is a very cost-effective solution for quick and easy manual sheet metal changes. Up to eight coils are fixed in the manual coilselector. The desired sheet metal is manually pushed into the downstream machine via a handwheel.

OPTION

Recoiler

With this recoiler, slits or wide strips can be easily recoiled. The coils are wound tightly to a diameter of 508 mm and an optically clean coil is produced after wrapping and removal. The recoiler has a dancer arm, separating discs, a pneumatic felt brake, a motor and a hydraulic mandrel.

OPTION

Fully rubberized pich rollers

If you want to prepare your line for a film applicator, then the option with the fully rubberized rollers is ideal for you. This means that your line is ideally prepared for retrofitting a film applicator at any time and with ease. Fully rubberized pinch rollers available in both 1250 and 1500 mm.

OPTION

Roller shear for stainless steel

Upgrade the roller shear to one that is better suited for stainless steel.

OPTION

Guillotine shear for stainless steel

Upgrade the guillotine shear to one that is better suited for stainless steel.

OPTION

Upgrade speed

Standard feeding speed for EASY series is 25 m/min. You can upgrade the feeding speed to 35 m/min or 45 m/min.

Film Application

Film application equipment can essentially be mounted on all our infeed tables. Thanks to support rollers and rubberized feed rollers, the film is pressed onto the sheet metal without the risk of bubbles or wrinkles. The F-AG z2mo module has an extra arm with a tension spring that tightens the film during the return motion. This design is only applicable to systems with one decoiler.

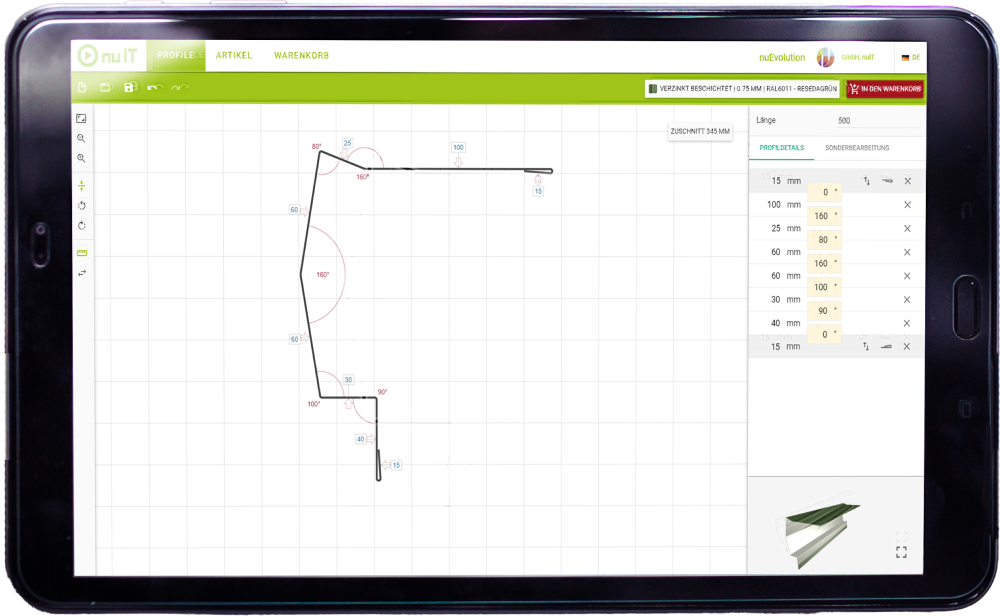

Discover the smart planning tool for sheet metal profiles

Efficient sheet metal processing begins and ends with nuEvolution from nuIT – the smart planning tool that revolutionizes your entire manufacturing process. Combine nuEvolution with the impressive power and agility of CIDAN’s machines for perfect oversight, great results, shorter lead times, and increased profitability. All you need is a tablet or laptop and your finger.

Technical specifications

| Model | EASY CUT 1250 | EASY PRO 1250 |

|---|---|---|

| Working width | 1250 mm | 1500 mm |

| Type | Cut to length | Cut to length |

| Steel1 | 1,0 mm | 1,5 mm |

| Stainless steel2 | 0,6 mm | 1,0 mm |

| Aluminum3 | 1,2 mm | 1,8 mm |

Support

We are always available for technical support and are happy to perform preventive and protective maintenance on your machines.

Get help choosing the right machine

Talk to one of our specialists and get answers to all your questions. Call +46 511 245 20 or contact us via email:

Trade in your old machine

We buy your old machine, regardless of brand and age, when you invest in a new one from us. Take the opportunity to invest in a more efficient future by upgrading to a new, smart, and fast machine. The fact that the new machines are also more environmentally friendly is an added bonus.

Spare parts

Do you need spare parts and accessories for your CIDAN, Forstner, or Thalmann machine? Take the opportunity to place your order to ensure your machines are always in top condition. Contact us via email, and we’ll take care of it for you.